Monday, May 20 2019

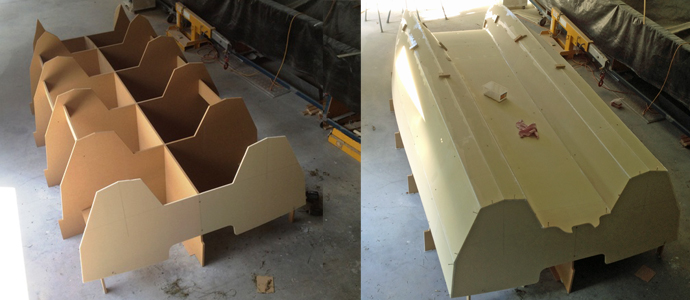

Ripple 3.2m Plain foam pre-cut kit.

Unfinished KIT project for sale at a heavily discounted price of AUD2250 inc gst ex Newcastle.

The builder has already glassed all the parts ready for assembly.

The package includes the MDF build frame and all epoxy, glass tapes and modifiers for construction.

The plain foam kit has a lighter lay-up than the DuFlex so will produce a lighter boat.

Contact us for more information.

P 02 4981 8288

E info@spiriteddesigns.com.au

Sunday, October 09 2016

This is our latest factory-built Ripple project for a customer from Queensland. Built from the Duflex foam kit it was kept as light as possible. The owner requested some personalised extras such as an in-built fuel tank under the Port forward seat with deck filler, fore and aft tow fittings, large beach wheels, davit lift fittings, gunnel fender strip and composite rod holders. For more information about this design check out the Ripple page

Thursday, September 29 2016

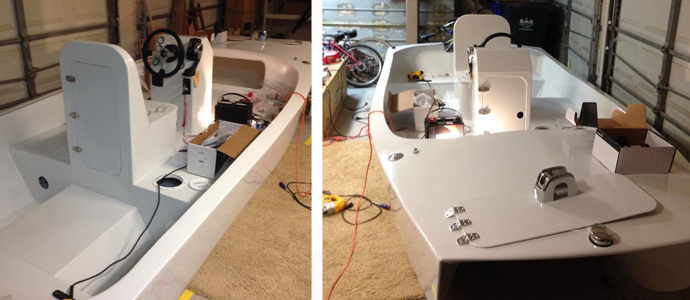

You may remember this Ripple which was sea-trialled in raw Duflex! Since then the owner has spent a lot of effort fitting this little boat out. There is storage below the helm seat, hydraulic steering, an anchor locker, bilge pump and even nav lights! The engine is a 15hp Mercury with electric start and tilt! All that's missing is the espresso machine! This would have to be the most elaborate fit-out of the smaller sized Ripple's so far.

Congrats go to the owner who has done a great job on the finish!

There is a Youtube video clip of the boat underway for anyone interested: click here

Sunday, July 03 2016

Apart from a few 4.2m Ripple's this is the first of the smaller models to be built using Duflex balsa. The reason being is that the builder is planning to build his larger live-aboard catamaran from the same product so a perfect way to practice!

We will bring you more about this project as it progresses...

Monday, February 22 2016

One of our builders in Queensland sent through some photos of his 3.6m Ripple tender which was built from the Dufllex foam kit. This is the same design as the one we built for another client in Qld also built in Duflex foam. This is the widened version of the original 3.6m Ripple as per BSF, the plywood boat in Tassie.

This Ripple is fitted with an in-built fuel tank as well as a few optional extras. The owner couldn't wait and took the boat out for sea-trials unpainted! The raw Duflex boat looks quite unusual but at least he knows it will float!

We will return with more photos when the boat is fully finished...

Thursday, May 28 2015

The 4.2m Ripple recently built and delivered to the client in Brisbane has been recieved. The engine and fit-out has been done and the new owner had a brief opportunity to take the boat for a quick run before the all important lift with his new crane onto the roof of his power cat. He was very impressed with the liveliness and speed of the boat even though he didn't want to over-rev the new engine. The boat will be well-tested this weekend when the owner plans to spend the this time out in Moreton Bay.

We have requested some photos of the boat underway so will post these as soon as we have them.

Wednesday, April 29 2015

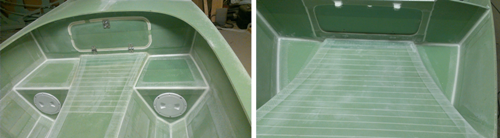

This project is now complete and awaiting pick up. The boat will be delivered directly to the engine dealer who will be fitting a Tohatsu 30hp in Qld.

This boat was customised for wheelchair access and use with a lift-out door in the hull on the Port side. Another inclusion is folding lifting fittings that have been recessed into the floor allowing for the boat to be craned onto the roof of the mothership. Supplied with the boat are custom-made cradles for the boat to sit in, these will come in handy when loaded onto the truck for the trip North.

This boat was built from the Duflex foam kit for maximum weight-saving but also providing excellent structural properties. The completed weight of this boat is 155kg.

For more information on our Ripple Tenders, click here

Monday, March 16 2015

This project for a client in Queensland is structurally complete with fairing almost done. The custom features include a full self-draining wet-deck with flush style fittings and a side access door in the hull.

The structure has been built from the Duflex foam kit and is promising to be very light in hull weight. This boat has been customized for wheelchair access and use. Extra reinforcement has been designed into the door cut-out with tension latches securing the door.

This is a great concept and size for not only a tender as this boat will be used but also as a fishing or day boat.

For more on this design click here

Saturday, November 15 2014

A new and interesting project underway is a customised 4.2m Ripple design. We are building this boat for a client who requires the boat wheelchair accessible. It will have a custom side access door on the Port side where the loading ramp will be positioned.

The wet-deck will be contiuous except for a Starboard side steering console well as seen on the 4.2m Ripples built in Hervey Bay. This boat is built using the Duflex foam (Divinycell) kit for extra weight saving and it will be craned and stowed on the roof of the mothership in a cradle. Fitted with beaching wheels, lift fittings, bollards, fender strip and some other extras. We will keep you informed of progress with this project as we go.

For more on the 4.2m Ripple design please click here

Tuesday, October 28 2014

We had another opportunity to test out the 3.6m Ripple recently built. Firstly we took some photos of the boat with a single passenger. The boat was powered with the same engine as previously trialled, a 9.9hp Tohatsu 2 stroke. With ideal conditions the boat planed easily and was very responsive. Handling was good and the ride very comfortable.

Following this we loaded up the boat with supplies and went out for the afternoon, 2 adults and 2 kids. The boat was very comfortable even through the middle of the bay with some confused chop. The twin hulls cut through smoothly and delivered a level ride, there was no bouncing or hobby-horsing as often experienced on a monhull design. Being relatively light-weight the boat runs well just on the plane for a more efficient cruising speed. Sneaking along the shore-line the boat is still efficient at these low speeds. As reported before the boat was comfortable in size at anchor for lunch and a fish.

As a day boat, the Ripple proved itself as an ideal design with excellent performance, stability and ergonomics.

Friday, October 24 2014

Shipping a tender of this size to the other side of the world requires some planning. There are certain restrictions concerning the packing. If using timber to costruct the frame for the crate, it must be graded for this purpose to comply with the customs inspections. The crate for this boat has been made from alluminium which cannot harbour grubs or insects etc. Special care has been taken with how the boat is supported and held inside the crate to avoid any damage. It will now be cladded prior to pick up.

Friday, October 24 2014

|

One of the owners of the three 4.2m Ripple tenders built in Hervey Bay, Allan Clark recently reported back on his experience with his 4.2m Ripple:

"The weight distribution is good, no cavitation and would not change a thing, runs well with great fuel economy. She beats anything when there is some chop happening, I love it!"

|

Wednesday, October 01 2014

We built this 3.6m Ripple from a Gaboon plywood kit and had the opportunity to do some sea-trials in the boat. This is a widened version of the standard design, the same as previously built for a client in Duflex foam. The extra beam provides for good space internally and additional stability.

The outboard used for the sea-trials was a 9.9hp Tohatsu which powered this boat well. The boat jumps straight onto the plane very quickly and performs efficiently at half or full throttle. The sea conditions were quite choppy at the time of trials and the boat had a comfortable ride for this sized boat with 2 adults. The twin hulls offered good support and held the boat considerably stable side to side while on the plane through the chop. We found that the engine tilt optimised performance when adjusted to a more vertical position (moving the leg aft) and eliminated any prop cavitation. This also improved the ride by lifting the nose and kept the boat drier.

The boat is lively, very responsive and rides high in the water. Even with 2 adults and 2 kids aboard, the boat planed easily with the extra weight settling the motion in the choppy conditions.

A 15hp engine would have provided good extra top speed and the extra power would be useful for recreational activities like towing kids on tubes etc. We also had the opportunity to trial the boat for a day out fishing. We had 2 adults and two kids aboard and found that this size was extremely user-friendly with plenty of space for this number of people. The stability at rest was impressive even with all passengers on one side.

Ergonomically the internal space worked well and was comfortable. The bridgedeck proved useful for cutting bait or preparing lunch (opposite ends!) or stretching out for a snooze. As with larger catamarans we found that drinks stayed put even with some chop about. As reported from Brian in Tassie, the front locker remained dry and kept a surprising amount of gear out of the way. The boat also rowed well considering it is not a displacement hull in this configuration. The 2 rowing positions gave the flexibility to move the crew around to keep the boat trimmed.

This boat weighed in at 67kg's which is quite respectable and can be lifted by two adults.

Wednesday, September 17 2014

This project is for a client who is awaiting the delivery of his brand new catamaran in La Rochelle France. After much research he decided that the 3.2m Ripple was the best tender for his new boat. He considered buying just the kit and having it built in Europe however the cost was more economical getting the boat factory built from us and shipping the completed boat.

It is testiment to the Ripple design that this client has ordered his tender from half way across the globe. Another benifit to having this boat built rather than buying a production tender was catering to his custom requirements. These included specific positioning of his lifting fittings, rubber fendering, in-built fuel tank and beaching wheels. The client had the wheels sent specially from Germany because he had had previous experience with this particular brand. The boat was built from the Duflex foam kit and weighs only 47kg's, another selling point to this design.

The simple and precise assembly of these kits keeps the build hours down to remain competetively priced in the market place if compared to production boats. This boat will be packed inside a custom-made crate to be shipped over to Europe.

For more information on our tender range, click here.

Wednesday, September 17 2014

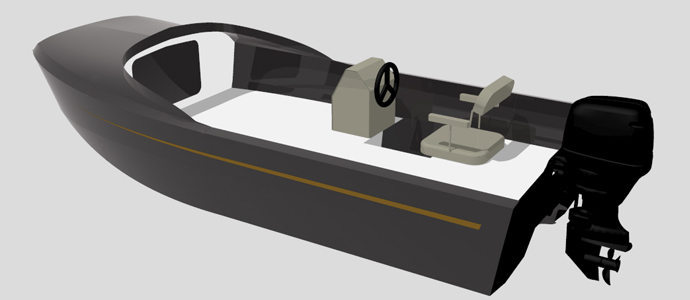

New off the drawing board is the 4.2m Raptor design. Designed specifically to suit aluminium construction, this is a planing hull with an expansive self-draining fishing deck. Set up with an offset steering console incorporated into the Starboard hull this will be a comfortable fishing or day boat. Commissioned for a client with a preference for aluminium as a build medium it will be interesting to see this project being built as compared with composite. The recommended engine size is 30hp with estimated cruise speeds of 25 knots and a top of 30 knots. The design is based on the successful Ripple range with customisation to suit alloy.

Other models will be added to this range in the future.

The Raptor can be supplied as a laser-cut kit which includes folded hull sections. The folded aft hull sections are supplied ready to install and are cut with some of the forward hull panels as part of this section. This build system reduces the amount of build time and welding required.

We have a builder to supply this model fully built to various requirements including a trailer. Please contact us if you would like some pricing on these options.

We will post updates of the first Raptor as it progresses. For any enquiries please contact us.

Monday, September 15 2014

The Wilson project is heading to completion now, it has been painted and the fittings are coming on. They have chosen the center console configuration for this design with the fishing deck surrounding and forward of this. There is also the option of the targa and hardtop option which would cover the helm and either side. Wes had fitted two 13 gallon tanks and this boat will be powered by a 30hp Nissan outboard engine.

' It's a good size at 14ft overall, plenty large for my boys and I

to do some river and bay fishing.'

If you want to see the Wilson project and how its progressing, like their facebook page.

Tuesday, April 22 2014

The 3.6m Ripple project mentioned previously has now been completed. The owners from Mackay Qld, happened to be on a road trip and collected the boat just after Easter. The load looked a little oversized but was secure once strapped on. This design was modified to include an extra 200mm of beam. The proportions look good offering more space internally. The bridgedeck is widened but still practical for rowing when seated with legs each side. The fit-out included lifting fittings and rubber fender strip. This wider design is available on request, for more information on our tender range, click here.

Tuesday, February 04 2014

We are currently building a 3.6m Ripple tender for a client, We are currently building a 3.6m Ripple tender for a client,

using the DuFlex foam kit option.

This kit was customised to include an extra 200mm of beam

and it will be well finished with all fittings and rub rail.

On completion it will be delivered to the client in QLD.

More progress photos will be posted soon.

For more information on our Ripple Tender designs and kits, click here.

Tuesday, January 21 2014

The latest launched 4.2m Ripple tender demonstrates the excellent carrying capacity

of this design:

- The interior volume is relatively

spacious for this size boat.

- The twin hulls offer good stability and support when loaded.

- This design has shown that it will accomodate the targa and hardtop efficiently.

Versatile kit packages offer a range of different materials to suit different preferences and budgets.

- Gaboon plywood kit packages have been popular for it's economical cost. Keeping the build cost low.

- DuFlex kit options have been popular for those preferring a more high-tech build material.

See our Ripple Tender page for more information.

Thursday, January 09 2014

Launched over christmas, this project from Victoria is now out on the water.

The clients are happy with their Ripple tender and report

' Tender works a treat with a 15 Yamaha on it and rows really well.'

Saturday, January 04 2014

The Wilson family have all jumped in with great enthusiasm to build their very own 4.2m Ripple Tender.

Being overseas the Wilson's opted to buy the plans only and source their material locally. They are building from Gaboon plywood and doing a very nice job of it. It is so nice to see the kids getting involved and from what we hear they are the main driving force. What a great family bonding experience to all be involved in a project such as this.

For anyone interested in following their progress the link to their blog is www.facebook.com/OurFamilyBoatProject

Saturday, January 04 2014

An owner from Hervey Bay recently reported on his 4.2m Ripple tender after some thorough sea trials. He has promised some photos of the boat underway soon which we will post as soon as received. You can see his comments below:

"The 4.2m Ripple got up to 38KPH (24knots) and was very Smooth, took her out in a bit of rough stuff and she handled like a dream, was very impressed with her performance, my centre console design works well, even with 3 people she planed easy. On Xmas day I put 9 people on board to go to shore and she handled it like a dream could have fitted more as it did not seem crowded and she held the weight well buoyancy-wise. Does not seem to use much fuel either which is a blessing. Overall very happy and even my wife loves it."

Friday, December 20 2013

We received a couple of photos of the 3.2m Ripple design being built in Victoria and progress is good. At the time the boat was

primed and nearing painting stage, the owners are hoping to have it launched for Christmas.

Friday, December 20 2013

The three 4.2m Ripple Tenders were launched recently and look great, early reports are good with good performance and handling.

We are waiting for more feedback and detailed performance figures which we will post when available.

All three tenders were built from a DuFlex Balsa kit and are set up with an offset steering console to Starboard. The owners specifically chose DuFlex as the building material for its lightweight and strong characterisitics. One of these boats will be stored on the rood of the mothership.

The owners have done a beautiful job of finishing with all three boats fitted and finished identically.

Thursday, September 05 2013

3.2m Ripple Tender project underway in Victoria. 3.2m Ripple Tender project underway in Victoria.

The photos below show the Duflex Airex Foam kit recently assembled. Brian and Denise Jones are doing a very neat job, well done!

They are extremely impressed with their kit and wrote a few words on their work experience todate, please click here to read further.

Thursday, August 15 2013

Pictured above are three 4.2m Ripple Tenders being built in Hervey Bay. These are all built from DuFlex Balsa kits and set up with a steering console on the starboard side. The standard configuration for this design has the console in the centre of the boat. These will be launched soon, we will let everyone know more on this design as it progresses.

Saturday, April 20 2013

Below are some images of a project in Duflex Airex foam panel underway in Western Australia.The Spirited Ripple Tenders are a popular choice with this Duflex foam option producing one of the lightest tenders available.

For those of you interested in this range of designs, we have just introduced a 3.2m model. Study Plans are available.

Saturday, January 19 2013

G'day Craig,

Had BSF out on Lake Barrington on Saturday - 1st proper day trip - brilliant success. The for'd locker was so handy ! Blew up later on in afternoon, but I was determined to make it to the northern end of the lake so kept going. I reckon it was blowing 20 knots so a bit of a chop but she handled it fine. Reason I built the boat was for day trips and it was a brilliant success. Teddy the dog had a ball ! He got gamer as the day went on - climbing on to the foredeck even when arked up - how he didn't end up in the drink I don't know ! LOL

Catch you later & cheers, Brian

Various sizes available, for our Ripple tender information contact us

Tuesday, November 20 2012

The first Ripple tender was launched in Devonport Tasmania earlier this month. Brian Furmage built his 3.6m Ripple from a Gaboon plywood kit and has done a very nice job of it.This was Brian’s first DIY boat-building project and he reports that he enjoyed the experience. The boat named B.S.F, performed well reaching a top speed of almost 22 knots with a 15hp outboard. Brian reports that the boat is very responsive and handles well.

This boat is set up with a built-in fuel tank in one of the forward seats and neat lockers under the aft seats. The forward locker below the foredeck has proven to remain totally dry even in one of his trials in some rough stuff in open waters.Brian plans to use B.S.F as a commuter between his home and the yacht club further along the river.

B.S.F may stand for some profanities if misjudging the bridge on the way home from the yacht club or it may be an abbreviation of his name, let’s hope it’s the latter!

|

|